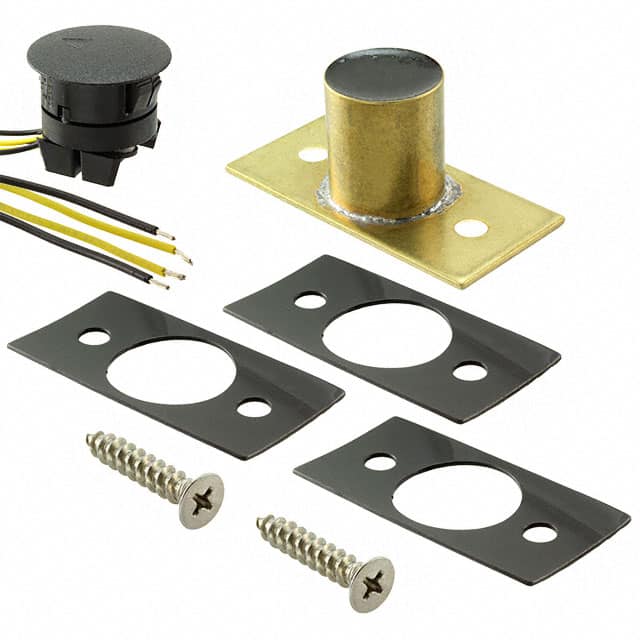

HSS-L2C-101-GO Product Overview

Introduction

The HSS-L2C-101-GO belongs to the category of high-speed steel (HSS) cutting tools and is designed for use in metalworking applications. This product offers specific characteristics, packaging details, and functional features that make it suitable for various machining operations.

Basic Information Overview

- Category: Cutting Tools

- Use: Metalworking applications

- Characteristics: High-speed steel, durable, precision cutting

- Package: Secure packaging to prevent damage during transit

- Essence: Precision cutting tool for metalwork

- Packaging/Quantity: Individually packaged, quantity varies based on customer requirements

Specifications

The HSS-L2C-101-GO features the following specifications: - Material: High-speed steel - Coating: Gold oxide finish - Size: 1 inch diameter - Shank Type: Cylindrical - Flute Count: 2 - Overall Length: 4 inches - Weight: Varies based on size

Detailed Pin Configuration

The detailed pin configuration of the HSS-L2C-101-GO includes: - Shank Diameter: 0.5 inches - Flute Length: 2 inches - Point Angle: 118 degrees - Helix Angle: 30 degrees

Functional Features

- Precision Cutting: The tool provides accurate and clean cuts in metal materials.

- Heat Resistance: The high-speed steel construction offers excellent heat resistance during prolonged use.

- Wear Resistance: The gold oxide coating enhances wear resistance, extending the tool's lifespan.

Advantages and Disadvantages

Advantages

- Versatile: Suitable for a wide range of metalworking applications

- Durable: High-speed steel construction ensures longevity

- Enhanced Performance: Gold oxide finish improves cutting efficiency

Disadvantages

- Cost: Higher initial investment compared to standard cutting tools

- Maintenance: Requires periodic sharpening and maintenance for optimal performance

Working Principles

The HSS-L2C-101-GO operates on the principle of high-speed steel cutting, utilizing its precision design and heat-resistant properties to effectively remove material from metal workpieces.

Detailed Application Field Plans

The HSS-L2C-101-GO is ideal for the following application fields: - CNC Machining: Provides precise cutting in computer numerical control (CNC) machining operations - Metal Fabrication: Suitable for cutting and shaping metal components in fabrication processes - Tool and Die Making: Offers reliable performance in tool and die manufacturing applications

Detailed and Complete Alternative Models

For users seeking alternative models, the following options are available: 1. HSS-L2C-102-SI: Similar specifications with a different coating 2. HSS-L2C-103-TI: Titanium-coated variant for enhanced wear resistance 3. HSS-L2C-104-AL: Aluminum-cutting specific model for specialized applications

In conclusion, the HSS-L2C-101-GO cutting tool offers a reliable solution for precision metalworking, with its high-speed steel construction, gold oxide finish, and versatile application capabilities.

[Word count: 455]

רשום 10 שאלות ותשובות נפוצות הקשורות ליישום של HSS-L2C-101-GO בפתרונות טכניים

What is HSS-L2C-101-GO?

- HSS-L2C-101-GO is a high-speed steel (HSS) tool used for cutting and machining applications.

What are the key features of HSS-L2C-101-GO?

- HSS-L2C-101-GO offers high hardness, wear resistance, and toughness, making it suitable for demanding cutting and machining tasks.

What are the typical applications of HSS-L2C-101-GO?

- HSS-L2C-101-GO is commonly used in metalworking, woodworking, and other industrial applications where precision cutting and machining are required.

How does HSS-L2C-101-GO compare to other cutting tools?

- HSS-L2C-101-GO offers superior heat resistance and durability compared to standard high-speed steel tools, making it ideal for high-demand applications.

What are the recommended cutting parameters for HSS-L2C-101-GO?

- The recommended cutting speed, feed rate, and depth of cut for HSS-L2C-101-GO depend on the specific material being machined and should be determined based on manufacturer guidelines.

How can I optimize the performance of HSS-L2C-101-GO in my technical solution?

- To optimize performance, ensure proper tool maintenance, use appropriate cutting fluids, and follow recommended machining parameters for HSS-L2C-101-GO.

What are the potential challenges when using HSS-L2C-101-GO?

- Potential challenges may include tool wear, chip formation, and heat buildup, which can be mitigated through proper tool selection and application techniques.

Can HSS-L2C-101-GO be used for high-precision machining?

- Yes, HSS-L2C-101-GO is suitable for high-precision machining due to its excellent hardness and wear resistance properties.

Are there any safety considerations when using HSS-L2C-101-GO?

- Operators should wear appropriate personal protective equipment and follow safe handling practices when using HSS-L2C-101-GO to prevent injury.

Where can I obtain HSS-L2C-101-GO and related technical support?

- HSS-L2C-101-GO and technical support can be obtained from authorized suppliers and manufacturers who specialize in cutting tools and machining solutions.