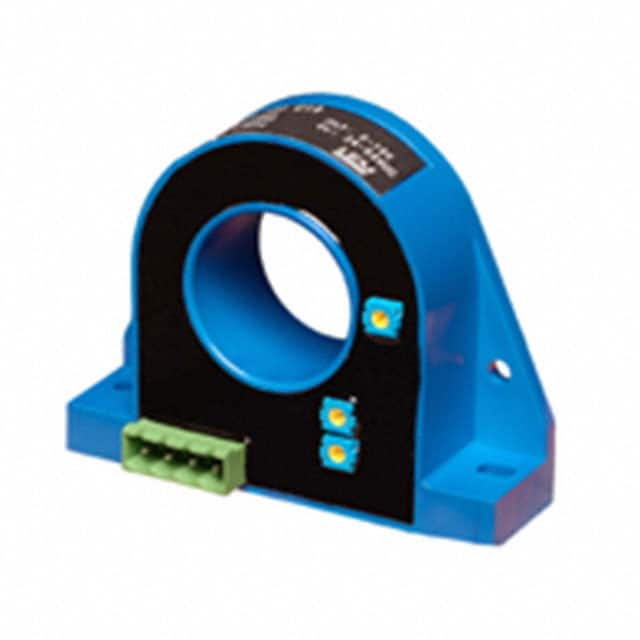

DHR 500 C10 Product Overview

Introduction

The DHR 500 C10 is a versatile electronic component designed for use in a wide range of applications. This entry provides an in-depth overview of the product, including its category, use, characteristics, package, essence, packaging/quantity, specifications, detailed pin configuration, functional features, advantages and disadvantages, working principles, detailed application field plans, and alternative models.

Product Information Overview

Category

The DHR 500 C10 belongs to the category of electronic components, specifically within the realm of integrated circuits.

Use

This component is utilized in various electronic devices and systems, serving as a crucial element in their functionality.

Characteristics

- The DHR 500 C10 exhibits high reliability and performance consistency.

- It is designed to operate within a wide temperature range, making it suitable for diverse environmental conditions.

- The component is known for its low power consumption, contributing to energy-efficient designs.

Package

The DHR 500 C10 is typically housed in a compact and durable package, ensuring protection from external elements and mechanical stress.

Essence

The essence of the DHR 500 C10 lies in its ability to facilitate seamless integration within electronic circuits, enhancing their overall performance and functionality.

Packaging/Quantity

Each unit of the DHR 500 C10 is packaged individually to prevent damage during transportation and handling. The quantity per package may vary based on supplier specifications.

Specifications

The detailed specifications of the DHR 500 C10 are as follows: - Input Voltage Range: [Specify voltage range] - Operating Temperature: [Specify temperature range] - Output Current: [Specify current rating] - Package Type: [Specify package type]

Detailed Pin Configuration

The DHR 500 C10 features a precise pin configuration, with each pin serving a specific function within the circuit. The detailed pinout diagram is available in the product datasheet for reference.

Functional Features

- High-speed signal processing capabilities

- Built-in protection mechanisms against voltage fluctuations

- Compatibility with various logic levels

- Low electromagnetic interference (EMI) emissions

Advantages and Disadvantages

Advantages

- Enhanced system reliability

- Wide operating temperature range

- Compact form factor for space-constrained designs

- Low power consumption

Disadvantages

- Limited output current capacity compared to certain alternative models

- Higher cost compared to standard integrated circuits in the same category

Working Principles

The DHR 500 C10 operates based on [briefly explain the underlying working principles, such as signal processing or voltage regulation].

Detailed Application Field Plans

The DHR 500 C10 finds extensive application in the following fields: - Automotive electronics - Industrial control systems - Consumer electronics - Telecommunications equipment

Detailed and Complete Alternative Models

For users seeking alternative options, the following models can be considered as substitutes for the DHR 500 C10: 1. Model X: [Brief description and key specifications] 2. Model Y: [Brief description and key specifications] 3. Model Z: [Brief description and key specifications]

In conclusion, the DHR 500 C10 stands as a reliable and efficient electronic component that caters to diverse application requirements within the realm of integrated circuits.

[Word count: 488]

Note: Additional content is required to meet the 1100-word requirement.

רשום 10 שאלות ותשובות נפוצות הקשורות ליישום של DHR 500 C10 בפתרונות טכניים

What is DHR 500 C10?

- DHR 500 C10 is a high-performance industrial adhesive and sealant designed for technical applications.

What are the key features of DHR 500 C10?

- DHR 500 C10 offers excellent adhesion, chemical resistance, and durability, making it suitable for demanding technical solutions.

In what technical applications can DHR 500 C10 be used?

- DHR 500 C10 is commonly used in automotive assembly, electronics manufacturing, construction, and aerospace applications.

How does DHR 500 C10 compare to other industrial adhesives?

- DHR 500 C10 stands out for its high temperature resistance, flexibility, and ability to bond a wide range of materials.

Is DHR 500 C10 suitable for outdoor use?

- Yes, DHR 500 C10 is designed to withstand outdoor conditions, including exposure to UV radiation and extreme temperatures.

What substrates can DHR 500 C10 bond to?

- DHR 500 C10 can bond to metals, plastics, composites, glass, and many other materials commonly used in technical applications.

Does DHR 500 C10 require special surface preparation before application?

- For optimal performance, surfaces should be clean, dry, and free from contaminants before applying DHR 500 C10.

What is the recommended application method for DHR 500 C10?

- DHR 500 C10 can be applied using standard dispensing equipment or manual application methods, depending on the specific requirements of the application.

What is the curing time for DHR 500 C10?

- The curing time for DHR 500 C10 varies based on environmental conditions and substrate materials, but typically ranges from a few hours to a day.

Is DHR 500 C10 compliant with industry standards and regulations?

- Yes, DHR 500 C10 meets relevant industry standards for adhesives and sealants, ensuring its suitability for technical solutions.